Factory injection molding custom rubber products

Rubber injection molding

plastic mold maker factory custom rubber bump stop

Mold Material:45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc .

Mold Type:Plastic Injection Molding

Product Material:ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc

Mold Standard:HASCO, DME, MISUMI, JIS, LKM, etc.

Mold Tooling Equipment:Lathe,Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine

Gate Type:Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc.

Runner Type:Cold Runner or Hot Runner

Cavity:Single or Multi cavities

Mold Life:45#:50,000 to 100,000 shots

P20:100,000 to 200,000 shots

718: 200,000 to 300,000 shots

H13: 300,000 to 500,000 shots

Lead Time:Generally mold making will take around 30 days and 7-10 day to mass production

Package:Wooden packing box for molds and Generally inner packed in opp bags, outside packed in standard export carton with shipping marks, and the cartons will be full of bubble bags.

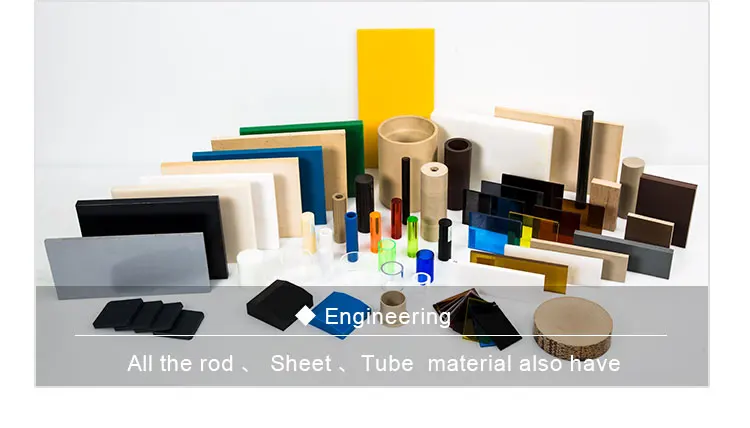

| Product name | plastic mold maker factory custom rubber bump stop |

| Material |

PTFE,POM,PVC,Nylon,PEEK,PU,PA,Acrylic,PE,UPE,etc. |

| Color |

White,black,or as your requirement |

| Diameter |

5-200mm,or customized |

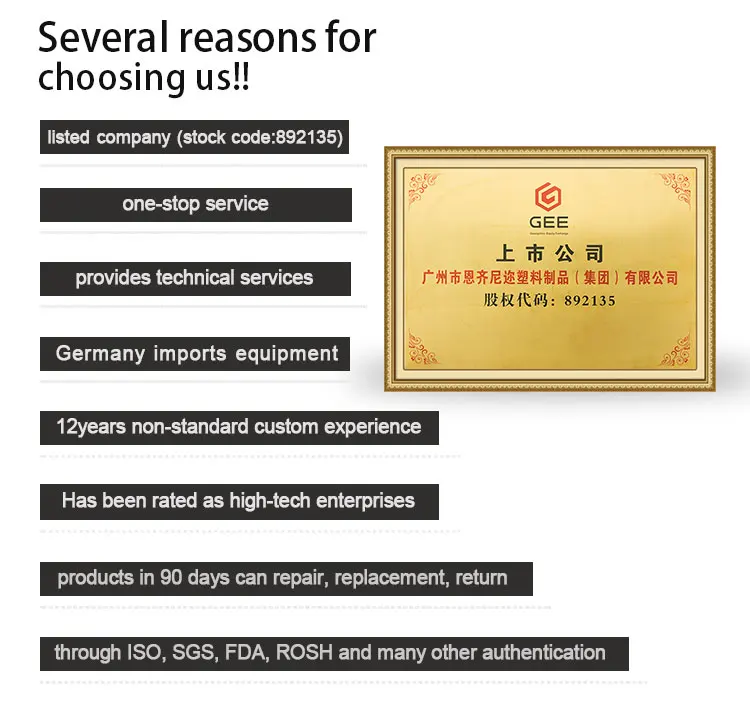

| Certification | ISO9001,SGS,Test Report,RoSH |

| Shape |

Sheet, rod, tube, gear, rack,pulley, guide rail, Plastics fittings,and so on |

| Packing | Plastic bags,Cartons,Wodden case,Pallet,Container,ect. |

| Other |

24 hours instant and comfortable customer service. Shipping status notification during delivery. Regular notification of new styles & hot selling styles. |