Product Description PEEK(Polyetheretherketone)is a kind of heat-resistant, high performance thermoplastic special engineering plastics. It has good mechanical properties and chemical resis

Features:

1. Excellent strength, and stiffness up to 500°F (260°C)

Product Description

PEEK(Polyetheretherketone)is a kind of heat-resistant, high performance thermoplastic special engineering plastics. It has good mechanical properties and chemical resistance, abrasion resistance, and hydrolysis resistance properties etc.; it has a light proportion and self-lubricating properties.

1. Excellent dimensional stability

2. Low coefficient of linear thermal expansion

3. Good mechanical properties at elevated temperatures

4. Good resistant to hot water and steam

5. Bearing grade PEEK has excellent wear characteristics

6. UL 94 V-0 flammability rating (0.059" thickness)

7. Very low smoke and toxic gas emissions when exposed to flame

8. Outstanding mechanical properties even at high temperatures

9.Optimized balance of stiffness, tensile strength and impact strength.

10.Continuous operating temperature up to + 260°C and briefly even up to +300°C.

GuangZhou Engineering Plastics Industries (Group) Company, has studied and applied this material in many industries for many years. Due to very good processing properties, it can be filled with carbon fiber, Fiberglass and MoS2 etc. In order to improve lubrication performance and mechanical strength further.

1.PEEK-1000

This general purpose grade is unreinforced and offers the highest elongation and toughness of all PEEK grades. The newly available black PEEK 1000 is ideal for instrument components where aesthetics are important, as well as for seal components where ductility and inertness are important.

2.PEEK-HPV

Carbon fiber reinforced with graphite and PTFE lubricants,our newest grade of PEEK offers the lowest coefficient of friction and the best machinability for all PEEK grades. Anexcellent combination of low friction,low wear,high LPV,low mating part wear and easy machining,make it ideal for aggressive service bearings.

3.PEEK-GF30

The addition of glass fibers significantly reduces the expansion rate and increases the flexural modulus of PEEK. This grade is ideal for structural applications that require improved strength, stiffness or stability,especially at temperatures above 300°F (150°C).

4. PEEK-CA30

The addition of carbon fibers enhances the compressive strength and stffness of PEEK, and dramatically lowers its expansion rate. It offers designers optimum wear resistance and load carrying capability in a PEEK-based product. This grade provides more thermal conductivity than unreinforced PEEK - increasing heat dissipation from bearing surfaces improving bearing life and capability.

|

NO. |

Item no. |

Unit |

PEEK-1000 |

PEEK-CA30 |

PEEK-GF30 |

|

1 |

Density |

g/cm3 |

1.31 |

1.41 |

1.51 |

|

2 |

Water absorption(23℃ in air) |

% |

0.20 |

0.14 |

0.14 |

|

3 |

Tensile strength |

MPa |

110 |

130 |

90 |

|

4 |

Tensile strain at break |

% |

20 |

5 |

5 |

|

5 |

Compressive stress (at 2% nominal strain) |

MPa |

57 |

97 |

81 |

|

6 |

Charov impact strength(unnotched) |

KJ/m2 |

No break |

35 |

35 |

|

7 |

Charov impact strength(notched) |

KJ/m2 |

3.5 |

4 |

4 |

|

8 |

Tensile modulus of elasticity |

MPa |

4400 |

7700 |

6300 |

|

9 |

Ball indentation hardness |

N/mm2 |

230 |

325 |

270 |

|

10 |

Rockwell hardness |

-- |

M105 |

M102 |

M99 |

Color:Natural、Black、Khaki and so on.

PEEK Sheet Size: 500X1000X(Thickness:1-500mm)、620X1000X(Thickness:1-500mm) PEEK Rod Size: Φ6-Φ200X3000mm

PEEK Tube Size: (OD)30-600X (ID)20-500X length(500-3000mm)

Our Factory

Certification

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Application Area

1. Seals, Gears, Fittings.

2. Electrical components.

3. Medical instrument parts.

4. Aerospace parts, Valve Seats.

5. Semiconductor machinery components.

6. Food processing machinery components.

7. Bearings and bushings (bearing grade PEEK).

8. Pump and valve components, Wafer Carriers, Piston Rings.

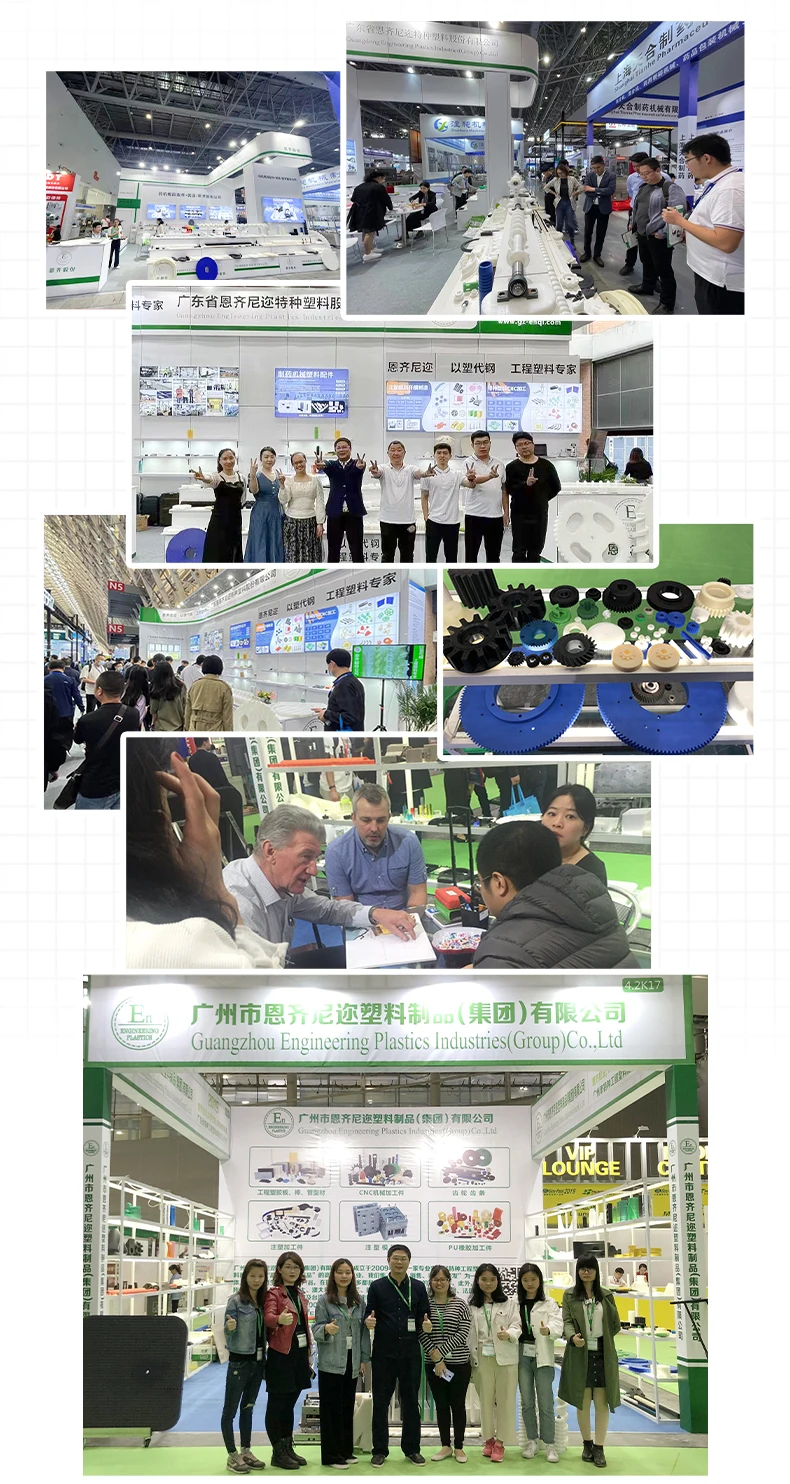

Our Exhibition

Cooperative Case

Cooperate with many well-known companies