PEEK(Polyetheretherketone)is a kind of heat-resistant, high performance thermoplastic special engineering plastics. It has good mechanical properties and chemical resistance, abrasion resistance, and hydrolysis resistance

Features:

1. Excellent strength, and stiffness up to 500°F (260°C)

PEEK(Polyetheretherketone)is a kind of heat-resistant, high performance thermoplastic special engineering plastics. It has good mechanical properties and chemical resistance, abrasion resistance, and hydrolysis resistance properties etc.; it has a light proportion and self-lubricating properties. Guangzhou Engineering Plastics Industries (Group) Company, has studied and applied this material in many industries for many years. Due to very good processing properties, it can be filled with carbon fiber, Fiberglass and MoS2 etc. In order to improve lubrication performance and mechanical strength further.

1. Excellent dimensional stability

2. Low coefficient of linear thermal expansion

3. Good mechanical properties at elevated temperatures

4. Good resistant to hot water and steam

5. Bearing grade PEEK has excellent wear characteristics

6. UL 94 V-0 flammability rating (0.059" thickness)

7. Very low smoke and toxic gas emissions when exposed to flame

8. Outstanding mechanical properties even at high temperatures

9.Optimized balance of stiffness, tensile strength and impact strength.

10.Continuous operating temperature up to + 260°C and briefly even up to +300°C.

Product Description

|

NO. |

Item no. |

Unit |

PEEK-1000 |

PEEK-CA30 |

PEEK-GF30 |

|

1 |

Density |

g/cm3 |

1.31 |

1.41 |

1.51 |

|

2 |

Water absorption(23℃ in air) |

% |

0.20 |

0.14 |

0.14 |

|

3 |

Tensile strength |

MPa |

110 |

130 |

90 |

|

4 |

Tensile strain at break |

% |

20 |

5 |

5 |

|

5 |

Compressive stress(at 2% nominal strain) |

MPa |

57 |

97 |

81 |

|

6 |

Charov impact strength(unnotched) |

KJ/m2 |

No break |

35 |

35 |

|

7 |

Charov impact strength(notched) |

KJ/m2 |

3.5 |

4 |

4 |

|

8 |

Tensile modulus of elasticity |

MPa |

4400 |

7700 |

6300 |

|

9 |

Ball indentation hardness |

N/mm2 |

230 |

325 |

270 |

|

10 |

Rockwell hardness |

-- |

M105 |

M102 |

M99 |

PEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

PEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fibre reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

PEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

PEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range of PEEK Rod is from -30°C to 250°C and has a short term maximum service temperature of 310°C.

Customized Service

Comprehensive Improvement of Services to Solve Your Problems

1. Product Design and Development.

2. Customized Processing According to Drawings and Samples.

3. Solve Your Problems with High Quality and High Level.

4. Customized Injection Mold Parts and CNC Processing.

5. Provide One-Stop Services for Your Project.

Our Factory

Application Field

1. Seals, Gears, Fittings.

2. Electrical components.

3. Medical instrument parts.

4. Aerospace parts, Valve Seats.

5.Semiconductor machinery components.

6. Food processing machinery components.

7. Bearings and bushings (bearing grade PEEK).

8.Pump and valve components, Wafer Carriers, Piston Rings.

Certificate

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

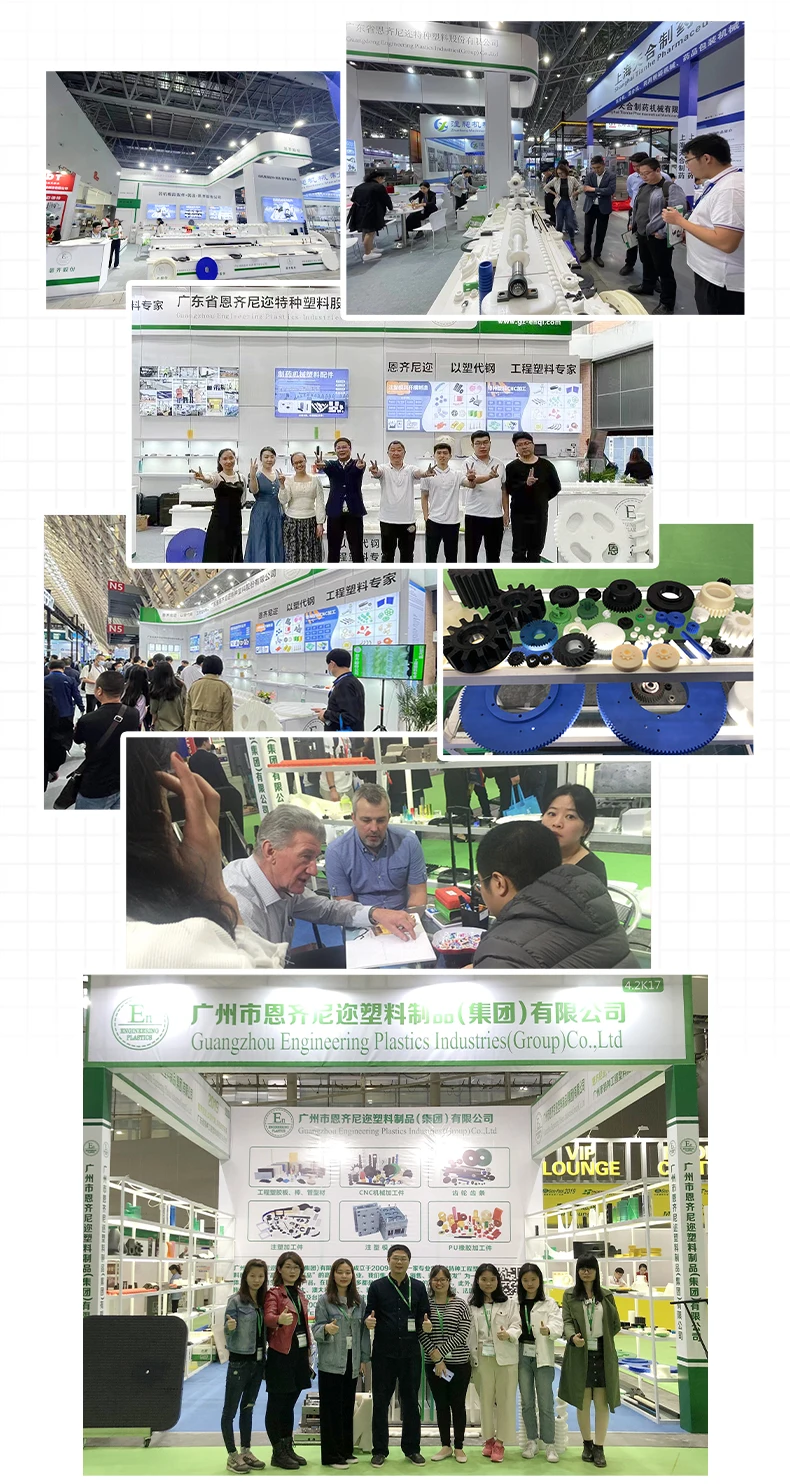

Our Exhibition

Cooperation

Cooperate with many well-known companies