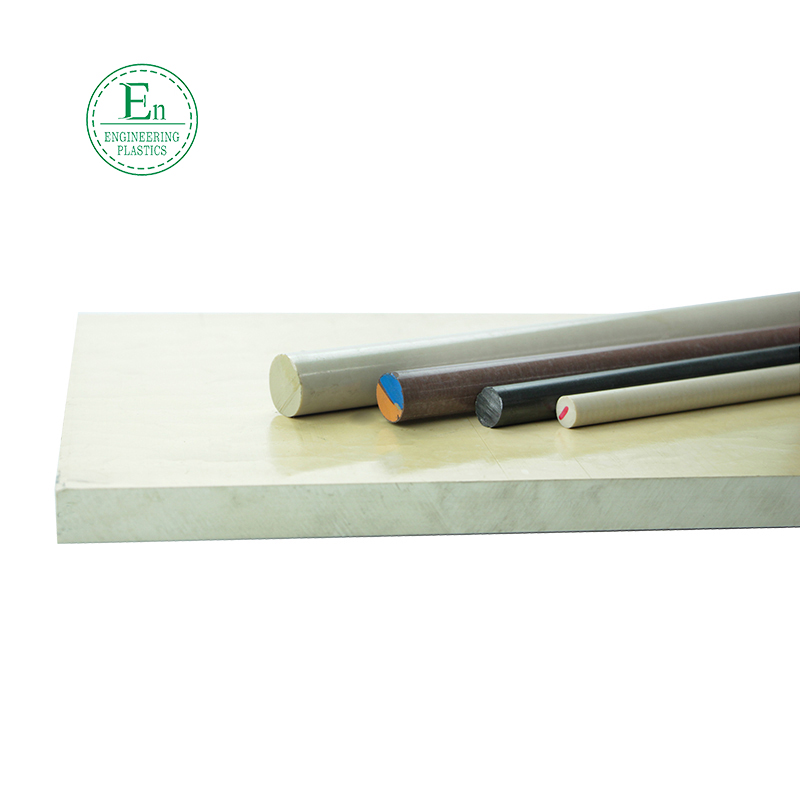

Wholesale plastic injection moulding products PEEK raw material plastic mould manufacturer

Features:

1. Excellent strength, and stiffness up to 500°F (260°C)

Wholesale plastic injection moulding products PEEK raw material plastic mould manufacturer

PEEK is a semi-crystalline thermoplastic with excellent mechanical and chemical resistance properties that are

retained to high temperatures. The processing conditions used to mould PEEK can influence the crystallinity

and hence the mechanical properties. Its Young\'s modulus is 3.6 GPa and its tensile strength is 90 to 100 MPa.

PEEK has a glass transition temperature of around 143 °C (289 °F) and melts around 343 °C (662 °F). Some

grades have a useful operating temperature of up to 250 °C (482 °F).The thermal conductivity increases nearly

linearly with temperature between room temperature and solidus temperature. It is highly resistant to thermal

degradation, as well as to attack by both organic and aqueous environments. It is attacked by halogens and

strong Brønsted and Lewis acids, as well as some halogenated compounds and aliphatic hydrocarbons at high

temperatures. It is soluble in concentrated sulfuric acid at room temperature, although dissolution can take a

very long time unless the polymer is in a form with a high surface-area-to-volume ratio, such as a fine powder

PEEK features advantages

Environmentally friendly non-toxic

Self-lubricating

Wear-resistant

Low noise

Impact resistance

High temperature resistance

High strength

High purity

Light weight

Corrosion-reisistant

Hydrolysis resistance

Good biocompatibility

Application

PEEK has been successfully used car manufacturing industry, because it has good friction resistance,

can replace metal (including stainless steel, titanium) manufacturing engine hood, auto bearing, seal,

brake pads, etc..

PEEK, due to its good mechanical properties, high temperature resistance, wear resistance, and high

pressure resistance, commonly used to manufacture compression valve plate, piston ring, seals, etc..

PEEK can withstand 3000 cycles of autoclaving at 134℃. It is non-toxic, light weight and corrosion resistant.

It is the closest material to human bone, so peek can be used instead of metal to manufacturer human bone.

PEEK can be processed into a variety of high precision aircraft parts, due to its hydrolysis resistance, corrosion

resistance and flame retardant performance, can be processed into aircraft parts and rocket engines of many

parts.

For injection molding, the products will be sent for 15 days. And we support OEM and ODM.