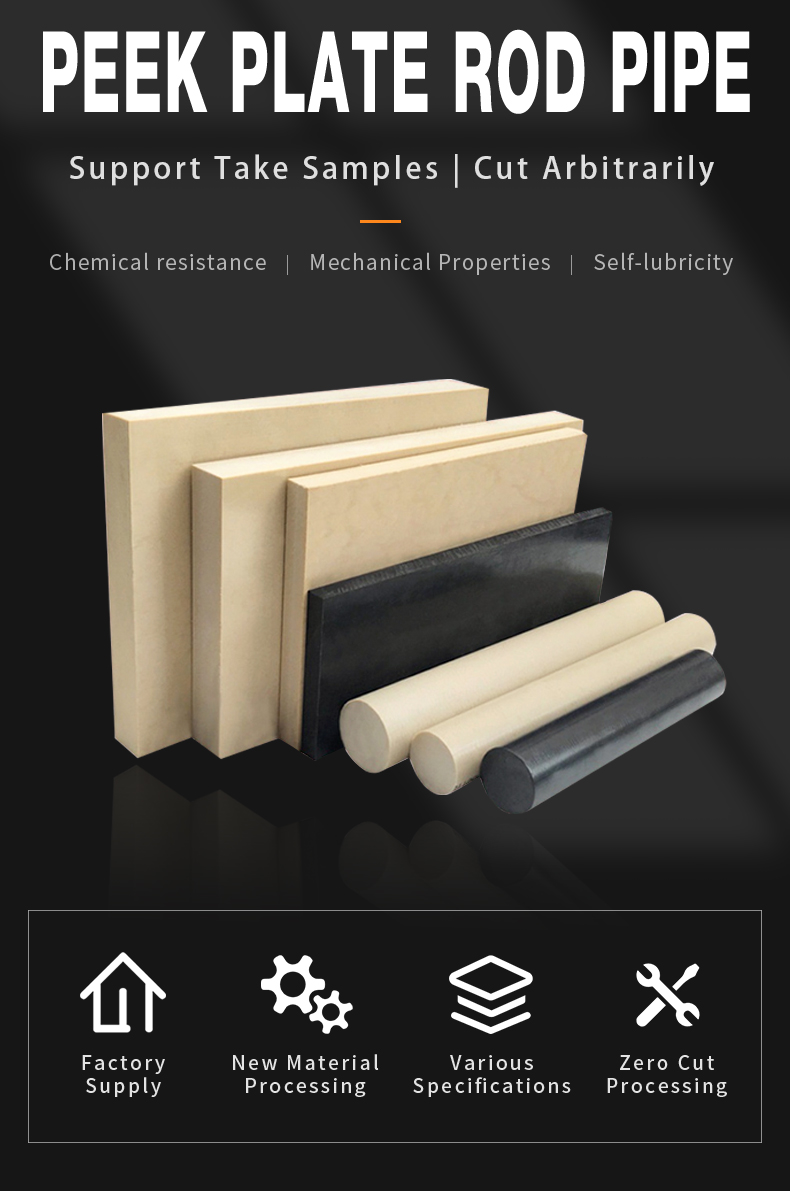

High Temperature Wear-Resistant New Material Peek Board Rod

Features:

1. Excellent strength, and stiffness up to 500°F (260°C)

Online wholesale plastic injection molding PEEK plastic PEEK sheet plate

PEEK is short for polyether ether ketone, which doesn’t make sense to many other than those with a strong

chemistry background. Put simply, it refers to the chemical structure of the polymer although most polymer

scientists identify PEEK as being part of the broader family of ketone polymers called polyarylether ketones

(PAEKs). This PAEK family covers a number of different compositions with different ratios of ether groups to

ketone groups, the most common of which is PEEK. Regardless of the specific chemistry it is the polyketone

chemical structure that makes PEEK so formidable in so many environments.

Why PEEK?

Superior wear resistance

Few polymers can match PEEK in terms of well-rounded wear resistance. Of course, “wear” is a general

term, and requires further explanation.

Abrasive wear refers to cutting action caused by the countersurface’s irregularities. Fatigue wear refers

to material deformation resulting from repeated pressure and stress. Friction is the resisting force against

motion, and though it isn’t “wear,” it is problematic nonetheless. PEEK’s properties provide resistance to

abrasive and fatigue wear, and it is a naturally low friction material. PEEK that is alloyed with PTFE

graphite and carbon fiber provides low wear rates at high pressure-velocity conditions in even abrasive

environments. Unfilled PEEK provides superior fatigue resistance and good wear resistance as well,

provided the maximum stress and velocity are low. Twenty percent (20%) PTFE filled PEEK (FE20)

offers a lower coefficient of friction and improved wear rates over unfilled PEEK.

Great processability

PEEK’s ease of processing has contributed to its wide acceptance in high volume commercial applications.

PEEK components are injection molding in high volume tooling equipped with hot runner systems,

machined from both extruded and injection molded stock shapes and even stamped and machined from

thin strip stock or film. Machining high performance thermoplastics can be a challenge because the

availability of the needed shape is often limited meaning the manufacturing cost increases due to

unnecessary machining swarf and the time to create it. PEEK’s high molecular weight and melt stability

enables it to be extruded into large cross sections such as rods greater than 200mm, plate up to 4” and

tubes with 2” thick walls. There are more than 50 different sizes of PEEK rod and plate stocked and

ready for immediate shipment. Additionally PEEK is one of the few high performance thermoplastics

that can tolerate the kind of extensive machining needed to produce components with complex

geometries one of reasons why it is found in so many diverse applications.

For injection molding, the products will be sent for 15 days. And we support OEM and ODM.