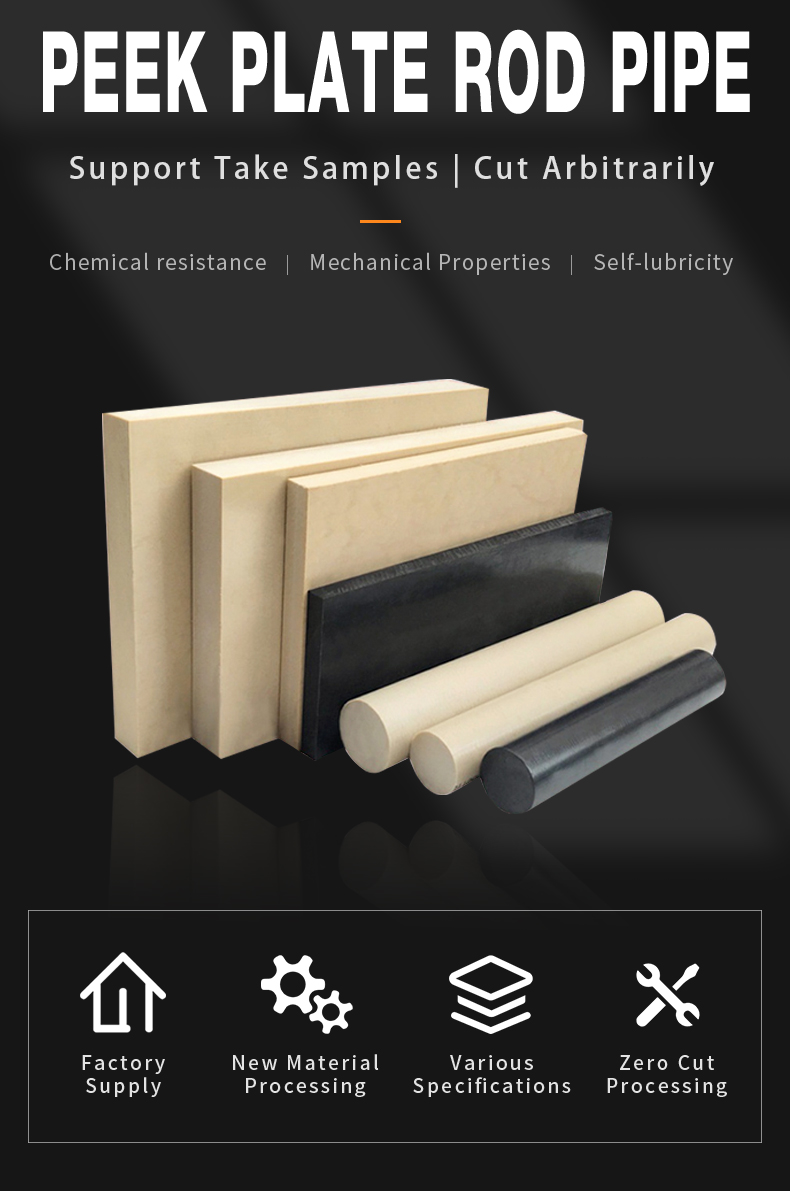

Hot selling Polyether Ether Ketone material flame retardant Peek Raw material

Features:

1. Excellent strength, and stiffness up to 500°F (260°C)

Polyether ether ketone (PEEK) resin is a special engineering plastic with excellent performance, which has more

significant advantages compared with other special engineering plastics. Positive high temperature 260 degrees,

excellent mechanical properties, good self-lubrication, chemical corrosion resistance, flame retardant, peel

resistance, wear resistance, resistance to strong nitric acid, concentrated sulfuric acid, radiation resistance,

super mechanical properties can be used in high-end machinery, nuclear engineering and aviation science and

technology.

Advantage:

Excellent heat resistance

Radiation resistance and high strength

Excellent long-term creep resistance and fatigue resistance

Excellent electrical insulation performance

Chemical stability is also very good

Good flame retardant

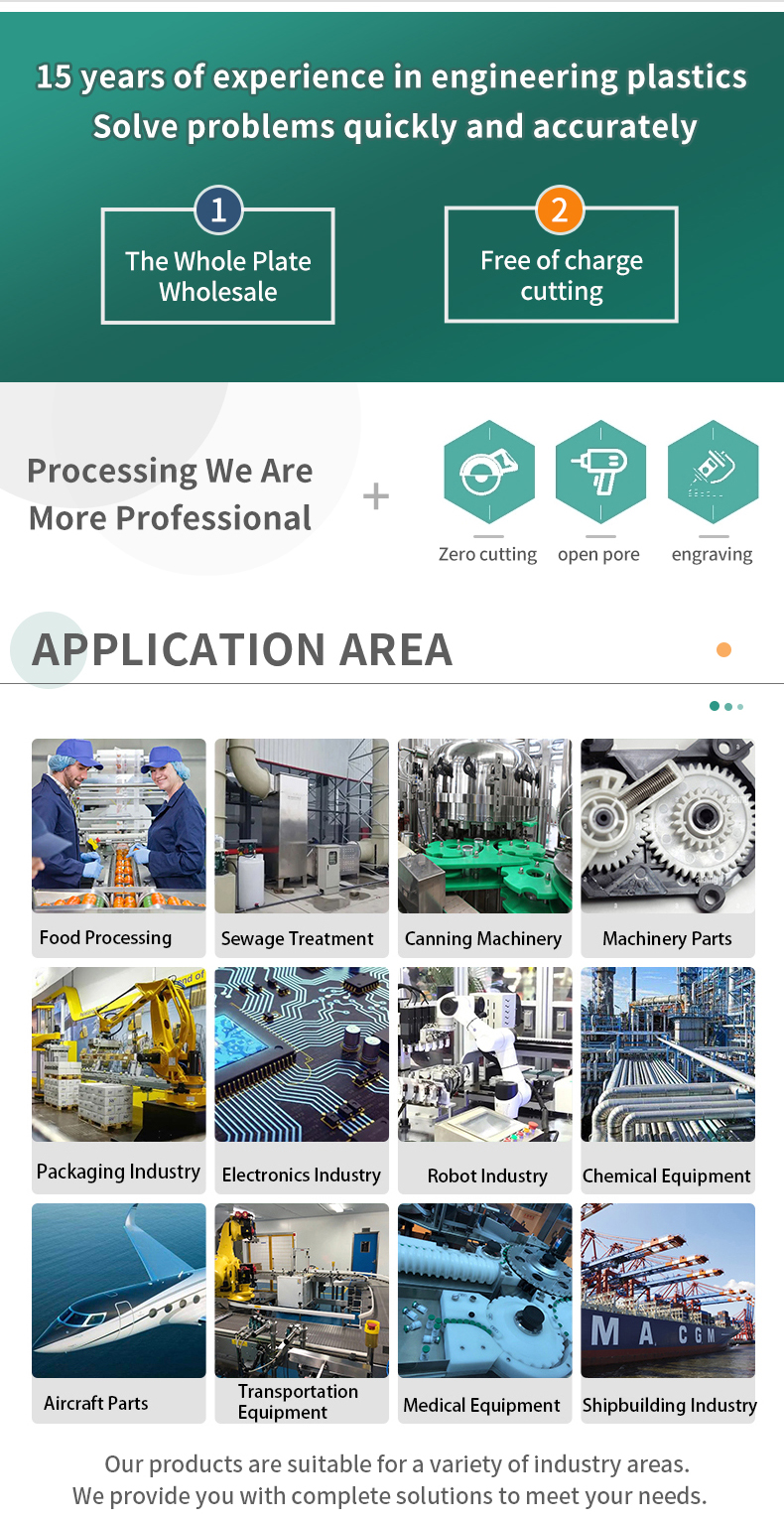

Appliance:

(1)Aerospace field:high-precision aircraft part

(2)Automobile manufacturing:it can replace metal (including stainless steel and

titanium) to manufacture engine hood, automobile bearing, seal and brake pad.

(3) Industry: compressor valve, piston ring, seal,etc.

(4)Medical devices:surgery and dental equipment. to replace metal to make human bones.

(5) Insulation material: semiconductor

For injection molding, the products will be sent for 15 days. And we support OEM and ODM.