One-stop service We provide product design and 3D printing services, we have more than 100 injection molding machines and 10 assembly lines, we can provide production operation and assembly services.

Why injection Moulding Injection Parts ?

For quality , injection is better, the smoothness and flatness can be done on the mold, and the strength is also good. Some transfers during mechanical processing, the sharp edges may be difficult to process beautifully . But mass injection need big quantity to open mould to decrease unit price because of expensive mould .

hot runner nozzle for plastic injection mold mould maker plastic injection mold plastic mould maker injection mold parts

Product Display

1.Plastic Injection Mold Making

Molds are constructed through two main methods:

standard machining and electrical discharge machining(EDM).

2.Plastic Injection Molding Products

We can customize all kinds of Engineering plastics products according to customers’drawings or samples.

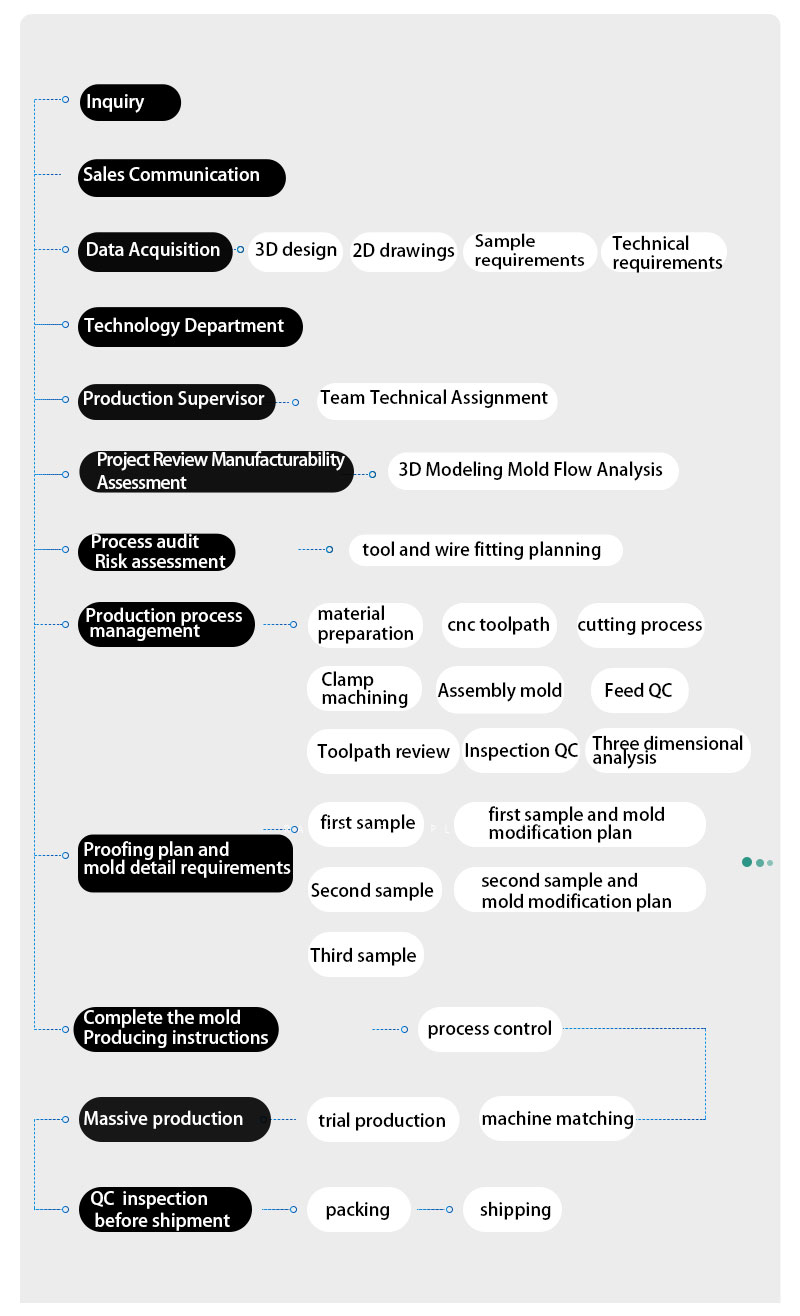

Injection Process

3. 500+ Material Choices Custom Injection Molding

Guangdong Engineering plastics company strive to be leaders in the custom plastics industry. That’s why we’re proud to offer a wide variety of Engineering materials that we use to manufacture our custom plastic products. Below is the list of materials that we offer for thermoforming and injection molding products for our customers.

Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE,

PC, PVC,PMMA(Acrylic),TRU,EPDM,NBR,Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,

PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc.

Our Exhibition