Product Description 1. Test tube is made of superior PET /PP material, it has a good chemical compatibility. Adapted to storage for most of polar organic solvent, weak acid, weak base. 2. PS test tube is manufactured with excel

Medical Moulding Injection

Product Description

1. Test tube is made of superior PET /PP material, it has a good chemical compatibility. Adapted to storage for most

of polar organic solvent, weak acid, weak base.

2. PS test tube is manufactured with excellent technique, can stand centrifuge speed up to 5000 rpm without

crack or leakage.

3. Multiple sizes and types can meet various test requirements.

4. Labels can be customized to meet specific test demand.

Pressure buckle (thread) desig Stitch position (thread), good sealing, no leakage of oil, durable High transparentbottleTransparent bottle body, smooth surface, clear and clean, such as crystal general, simple and generous

Embry PET material, quality assurance, does not contain bisphenol A, can be high temperature resistance, can rest assured to use Fruity and embryo With round mouth, thickening material, good toughness, quality assurance

Advantages of choosing PET test tubes

1. Easy to install: PET test tube has a flexible structure, which can meet various experimental needs. It can be easily installed and the operation is simple, making the operation easier.

2. Easy to clean: PET test tubes are easier to clean than other test tubes, and it is easier to remove the substances remaining on the tube wall, so as to avoid substances mixed into the experiment and affect the experimental results.

3. High temperature resistance: PET test tube has high temperature resistance, can withstand high temperature without being affected, and has strong impact resistance.

4. Recyclable: PET test tubes are recyclable, so that the waste during the experiment can be reused. The test tube can reduce the waste during the experiment, reduce the cost of the experiment, and protect the environment at the same time.

Medical Test Tube Plastic Injection Molding plastic casting

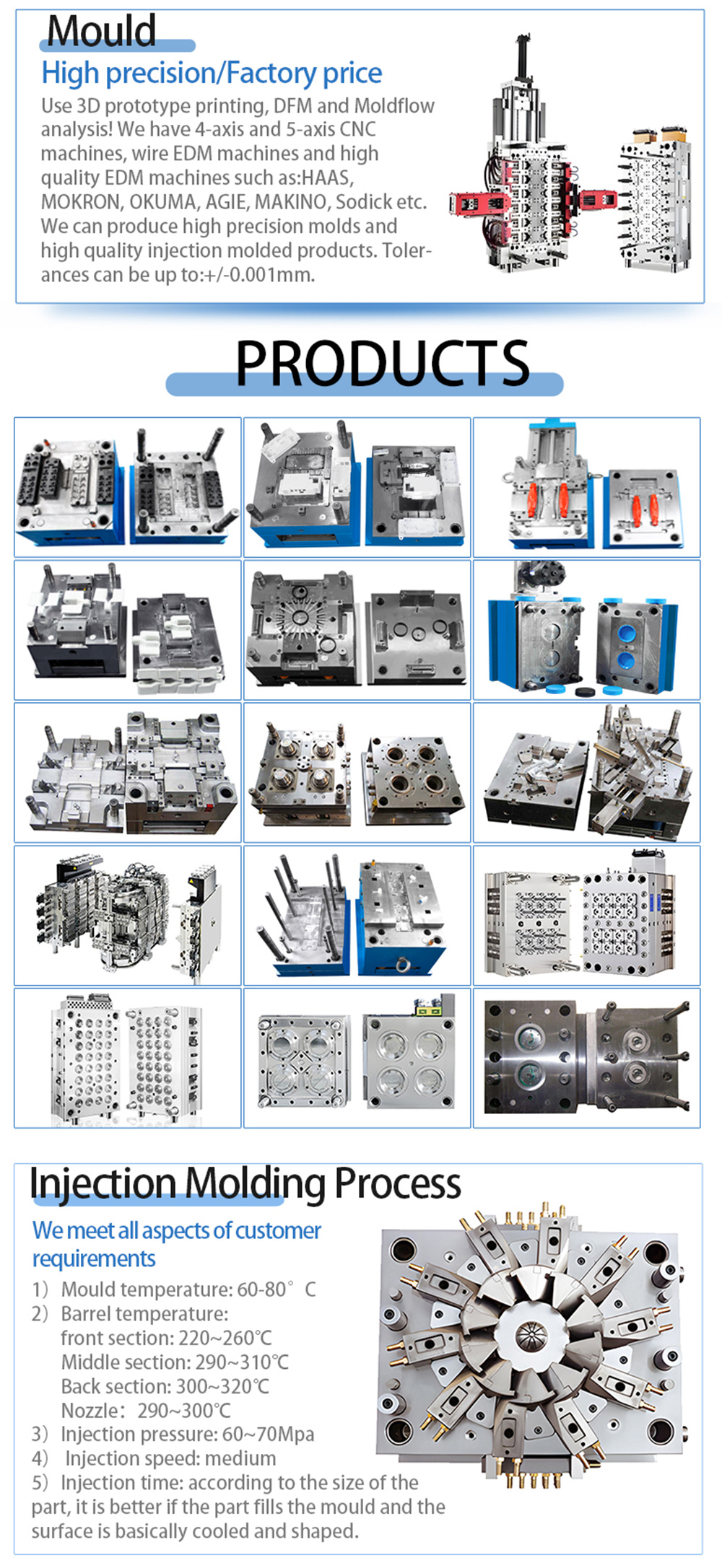

Your project begins when you meet with our expert mold engineers and toolmakers to design precision molds to produce injection molded products with tight micro tolerances. We have the capacity to manufacture over 100,000 parts per day, and we can also successfully produce short-run high-value, high-end specialty medical equipment accessories.

Features

1. These eco-friendly test tubes are made from strong, non-toxic materials.

2. Will not easily break, transparent color, allows you to see through easily, convenient to use.

3. Each tube is well sealed with a cap, suitable for storage of candies, handmade goods, samples, even liquid etc.

4. The tubes can also keep your items dry.

5. Put small items in these test tubes to prevent them from being lost and it is very easy to find and take them out

when you need them.

|

Product name |

Plastic Test Tube |

|

Classification |

Test Tube |

|

Material |

Plastic |

|

Type |

U shape |

|

Size |

Multiple Sizes |

|

Feature |

Eco-friendly |

|

Usage |

Lab Application |

|

Place of Origin |

Guangzhou China |

|

Package |

CTN |

|

Keyword |

Plastic test tube |

We have a wide range of customization:Moulding Injection

Industrial Moulding Injection,Electronic Moulding Injection

Automotive Moulding Injection,Medical Moulding Injection

PU Injection Molded Parts

Test tube

5. If you have some special request,we can customized for you.

For injection molding, the products will be sent for 15 days. And we support OEM and ODM.

PROFESSIONAL ENGINEER TEAMS AND SALES TEAMS

We have the professional engineer teams and sales teams. The maximum size of engraving machine in our manufacture is 2000mmx4000mmx400mm. Engineers and salesmen have more than 10 years of experience, specializing in medical, electronic and automotive products.

IMPORTED EQUIPMENT

We have the high quality CNC and EDM machine tools from HAAS、MOKRON、OKUMA、AGIE、MAKINO, such as, milling machines and 4 axis CNC milling machines, which have a capacity to process 200mmx4000 screw stably and precisely.

FAST DELIVERY

There are two shifts in the workshop every day. The fastest lead time of the plastic sheets is within one day. Thus, the delivery time is fast.

ONE- STOP SERVICE

We provide product design and 3D printing services. Having 58 engraving machines and CNC milling machine production lines, we can provide manufacture, operation testing and various services.

FACTORY PRICE WITH NICE QUALITY

We have IS09001 international quality management system, and Chinese manufacture cost control experiences! Therefore, when you compare us with others, we can help you save about 20% ~ 30% of manufacturing costs

EXCELLENT AFTER-SALES SERVICE

We provide excellent after-sales services to our clients for 3 years after their receipt of the products . Most of our customers have been working with us for more than 15 years ,with the co ntinuous trust,satisfaction and cooperation with us till now.

We also have multiple certifications ISO SGS FDA etc.

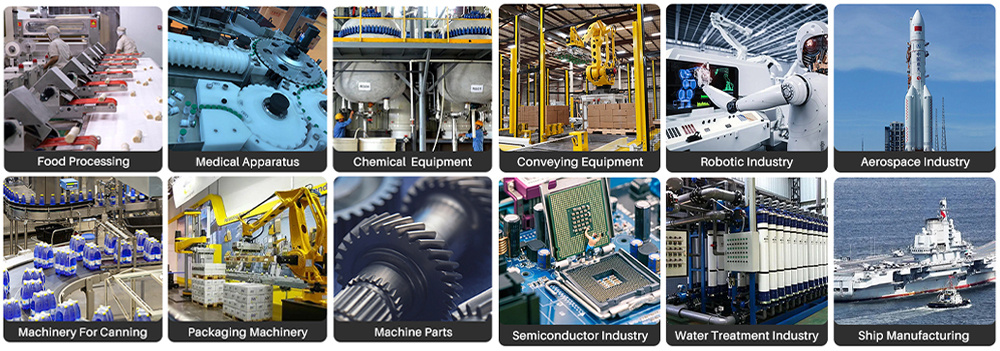

wide range of applications

Household utility ware, Auto components, Computer electronics, Electronics components,

Marketing samples, Medical & dental products, Model shops, toys, hobby,

New product design & development, Furniture Design, Civil Engineering, Construction.

For injection molding, the products will be sent for 15 days. And we support OEM and ODM.