Product Description Customize Your Static Seal Performance with the Right Elastomer 1.Lower viscosity 2.Faster cure rate 3.Less mold fouling 4.Improved mold flow and release 5.Improved

High performance fluoroplastic

Product Description

Customize Your Static Seal Performance with the Right Elastomer

1.Lower viscosity

2.Faster cure rate

3.Less mold fouling

4.Improved mold flow and release

5.Improved compression set resistance and tear properties

As technology evolves and markets intensify, performance demands across industries—including automotive, chemical processing, oil and gas exploration/production, and beyond—require components that can operate without downtime or mechanical breakdown. Specifically, these components need to withstand environments that are hotter and more corrosive, offer consistent and uninterrupted high performance, and be strong enough to last over the long term.

|

Product Type |

Nominal Viscosity, ML1 + 10 at 121 °C (250 °F) |

Polymer Fluorine Content, % Gravity |

Product Description |

Suggested Uses/Applications |

|

|

||||

|

A-Types: Gum Polymers |

||||

|

10 |

66 |

Ultra-low viscosity: excellent polymer rheology |

Coatings, viscosity modifier for higher viscosity types |

|

|

20 |

66 |

Low viscosity: excellent polymer rheology |

Cured with VC-50: injection molding applications |

|

|

50 |

66 |

Intermediate viscosity: excellent polymer rheology |

Cured with VC-50: compression, transfer, injection molding |

|

|

70 |

66 |

High viscosity: excellent physical properties |

Cured with VC-50: compression, transfer, injection molding |

|

|

160 |

66 |

Ultra-high viscosity: excellent physical properties |

Cured with VC-50: compression molding, high strength vulcanizates |

|

Our Factory

Certification

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Application Area

1. Seals, Gears, Fittings.

2. Electrical components.

3. Medical instrument parts.

4. Aerospace parts, Valve Seats.

5. Semiconductor machinery components.

6. Food processing machinery components.

7. Bearings and bushings (bearing grade PEEK).

8. Pump and valve components, Wafer Carriers, Piston Rings.

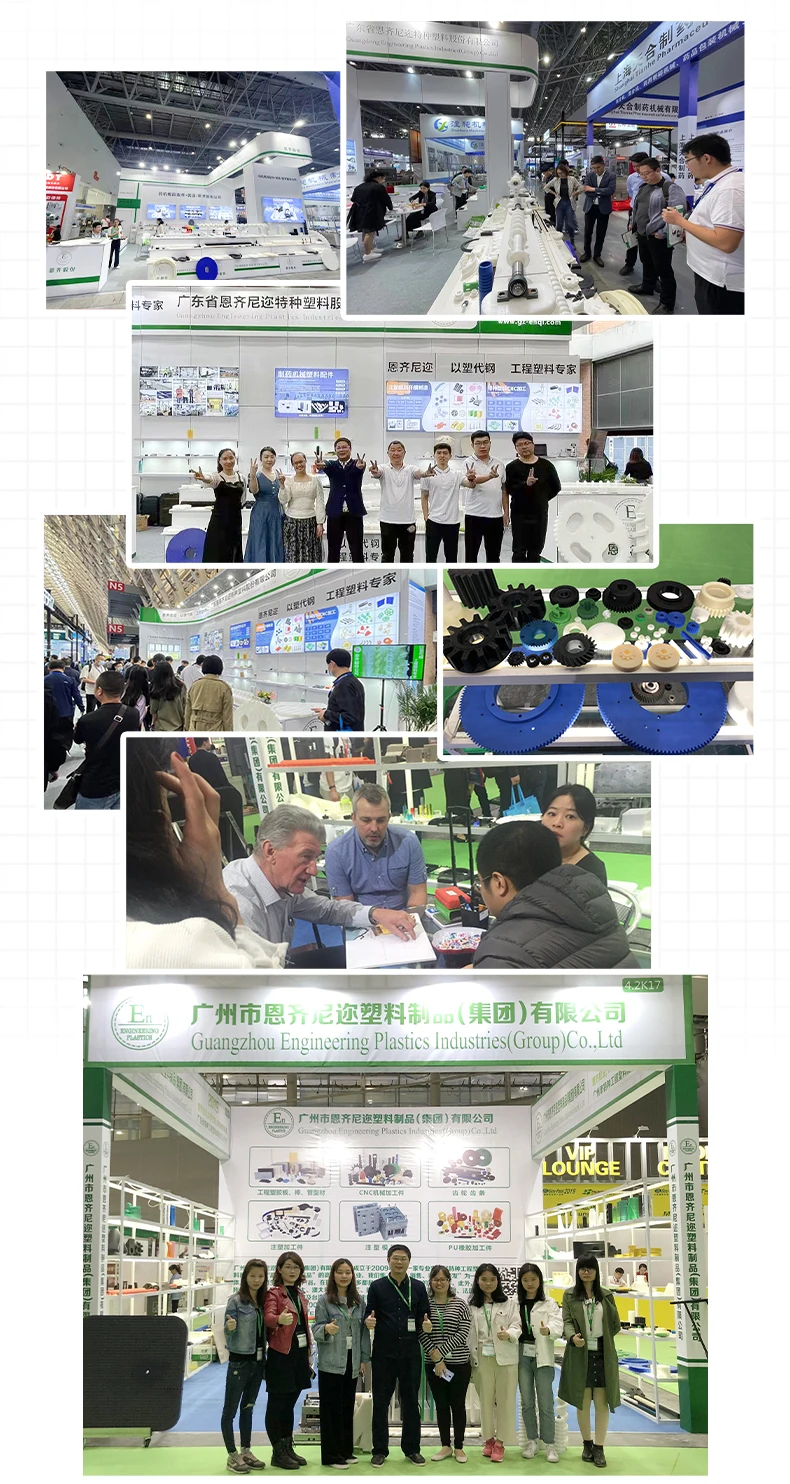

Our Exhibition

Cooperative Case

Cooperate with many well-known companies