How Much Does Injection Molding Cost? Injection molding is one of the leading processes for manufacturing plastics. It is widely used for mass-producing identical parts with tight tolerances. It is a cost-effecti

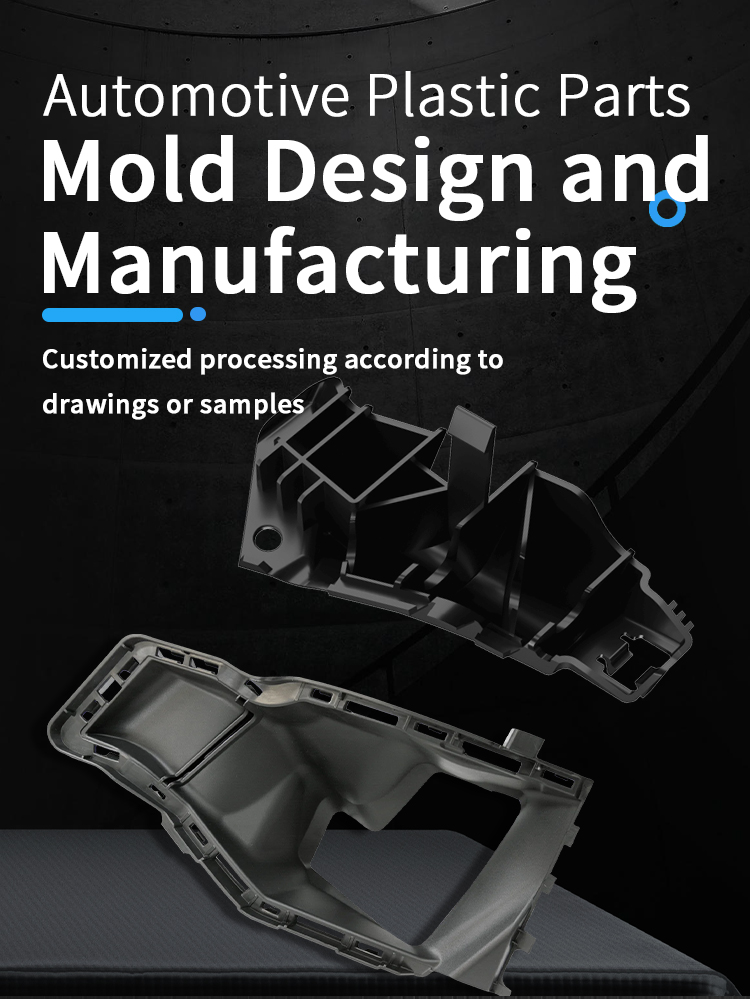

Automotive Moulding Injection

How Much Does Injection Molding Cost?

Injection molding is one of the leading processes for manufacturing plastics. It is widely used for mass-producing identical parts with tight tolerances. It is a cost-effective and extremely repeatable technology that yields high-quality parts for large series production.

It is a fast, intensive process where high heat and pressure are involved to inject molten material inside a mold. The molten material depends on the scope of the manufacturing project. The most popular materials are various thermoplastics, such as ABS, PS, PE, PC, PP, or TPU, but metals and ceramics can be injection molded as well. The mold consists of a cavity that accommodates the injected molten material and is designed to closely mirror the final features of a part.

Normally, the main cost driver in injection molding is the cost of the mold, also known as the tooling cost. The cost of mold design and building a mold depends on the required production volume, the complexity of the part design, mold material, and the process used to create the mold.

Simple low-volume 3D printed molds can cost as little as $100, while the cost of designing and manufacturing complex molds for high-volume production may hit the $100,000 mark. Despite the considerable fixed start-up costs, the injection molding process has low variable costs due to the inexpensive thermoplastics materials, short cycle times, and the labor needs decrease progressively due to automation and economies of scale. This means that the variable costs of production are low and the process becomes more efficient and the cost per part decreases at higher volumes as the costs get distributed among hundreds or thousands of parts.