Choosing the Best Plastic for Plastic Injection Molding Choosing the right plastic for plastic injection molding can be difficult—there are thousands of options in the market from which to choose, man

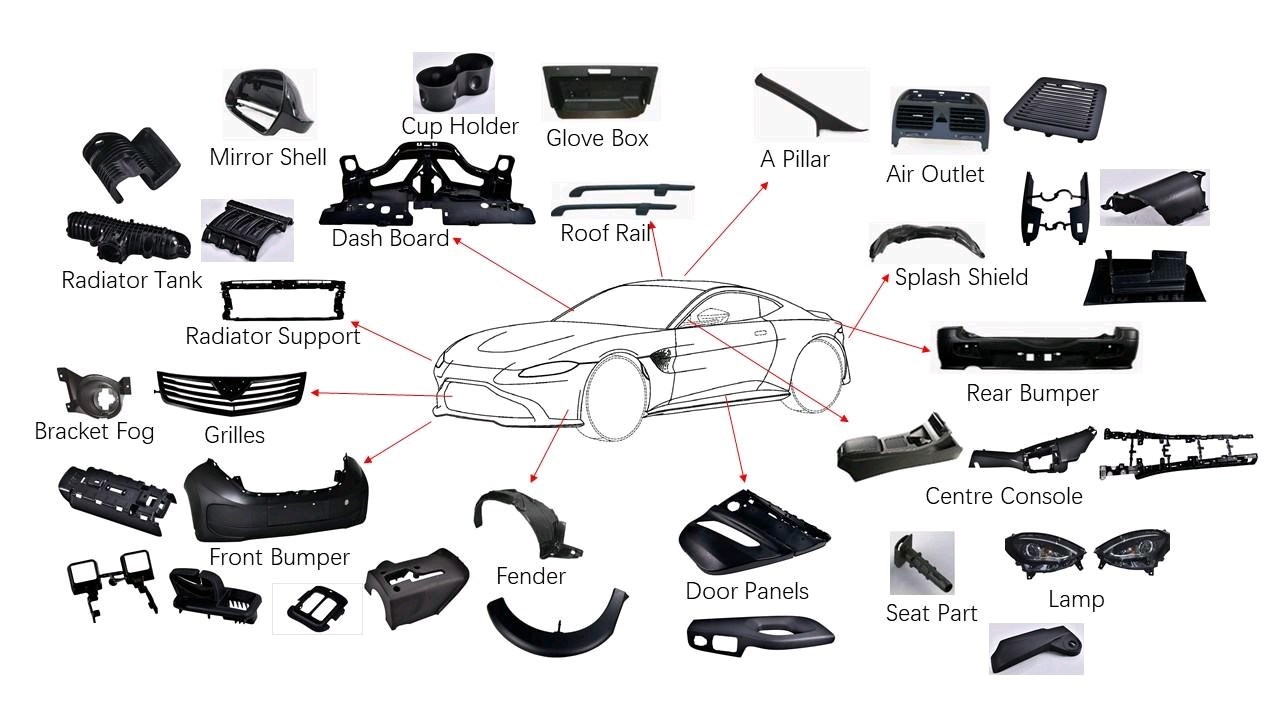

Automotive Moulding Injection

Choosing the Best Plastic for Plastic Injection Molding

Choosing the right plastic for plastic injection molding can be difficult—there are thousands of options in the market from which to choose, many of which will not work for a given goal. Luckily, an in-depth understanding of the desired material properties and intended application will help narrow the list of potential options into something more manageable. When considering the application, it is important to keep in mind the following questions:

1.Where will the part be used?

2.How long is its operational lifespan?

3.What stresses are involved in the application?

4.Does aesthetics play a role, or is the performance of paramount importance?

5.What are the budget constraints on the application?

Similarly, the questions below are useful when determining the desired material properties:

1.What are the mechanical and chemical characteristics needed from the plastic?

2.How does the plastic behave when heating and cooling (i.e., thermal expansion and shrinkage, melting temperature range, degradation temperature)?

3.What interactions does the plastic have with air, other plastics, chemicals, etc.?

A good pointer to keep in mind is material selection also depends on the product design, both in the application and in complexity. For example, designs calling for bendable sections/living hinges will require a strong yet flexible plastic like polypropylene. Similarly, structural parts that must be resistant to chemicals, abrasions, etc. should prioritize plastics like PEEK Product, Nylon Products, and others within these families.