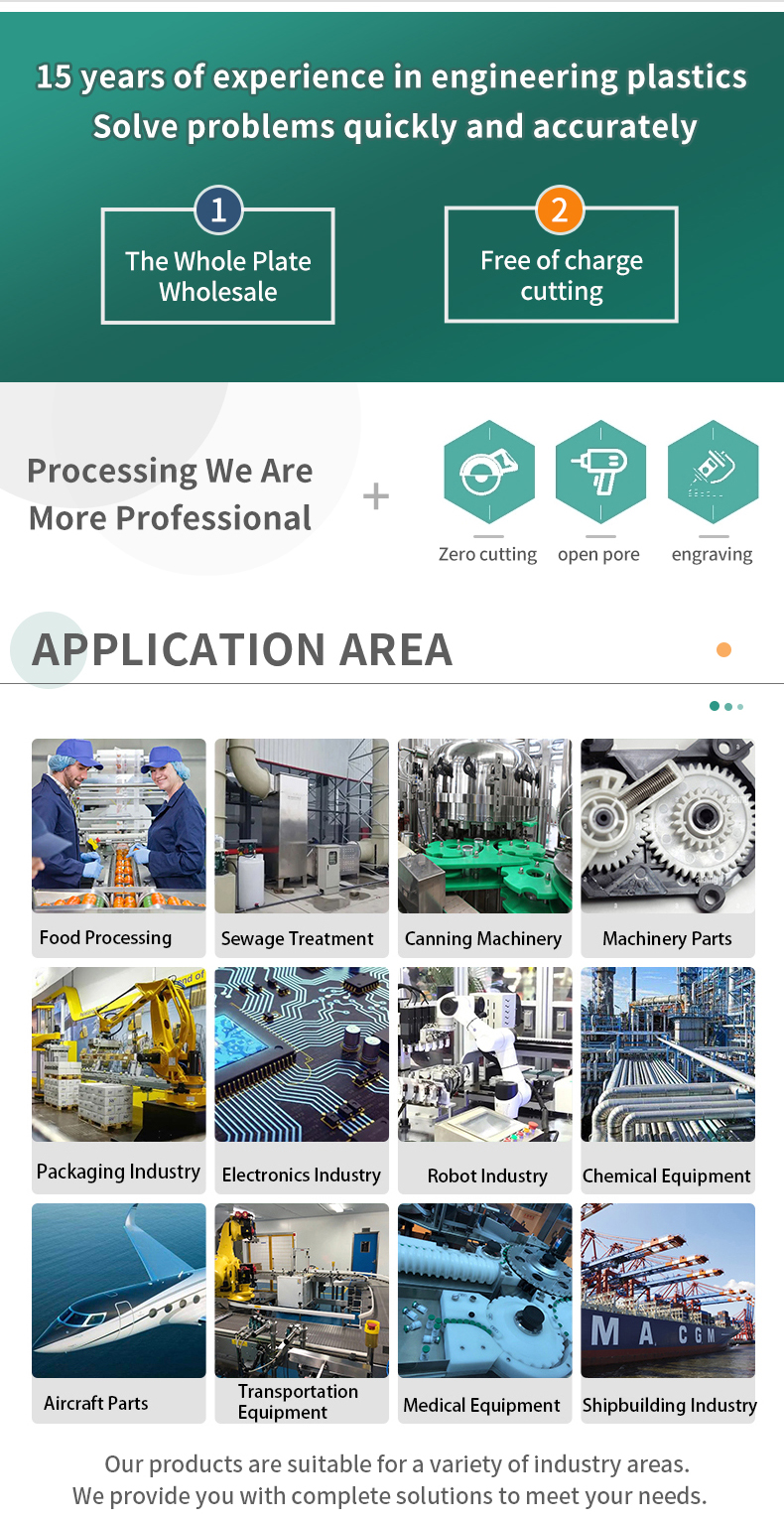

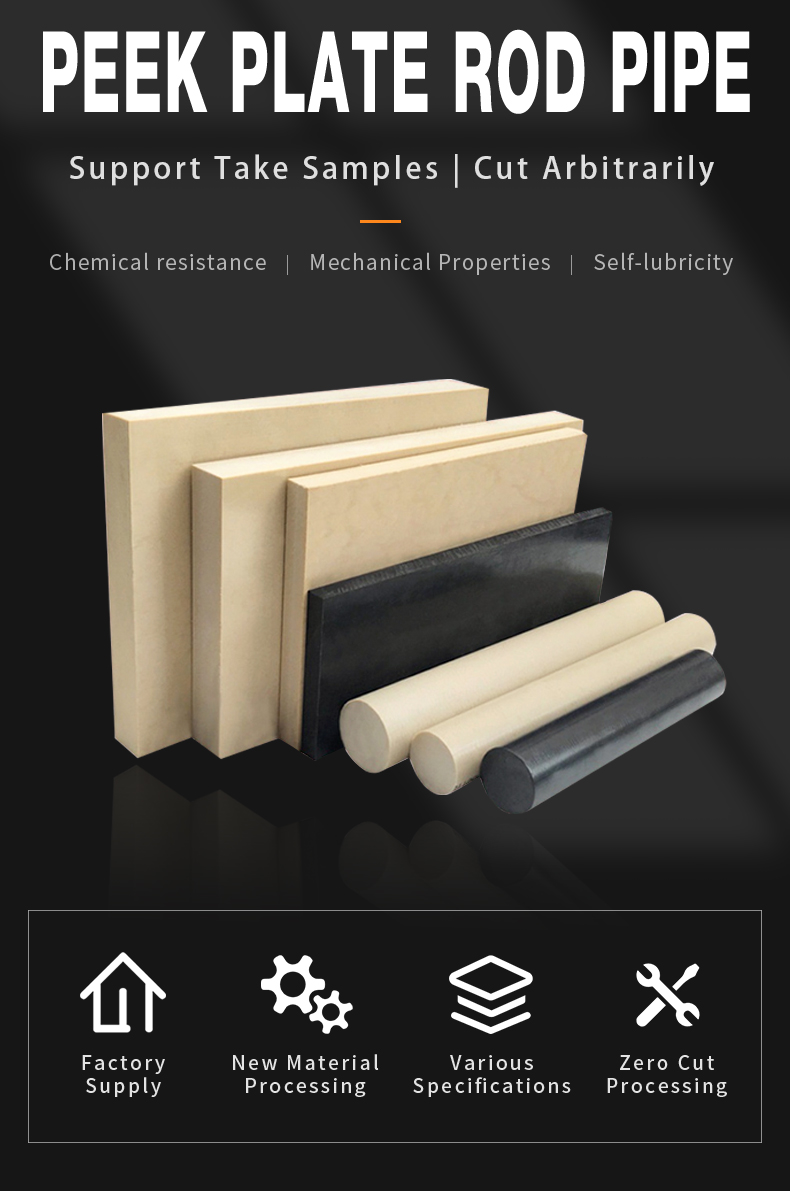

OEM fire resistance PEEK sheet wholesale PEEK board PEEK Plate

Features:

1. Excellent strength, and stiffness up to 500°F (260°C)

OEM fire resistance PEEK sheet wholesale PEEK board PEEK Plate

PEEK is a kind of heat-resistant, high performance thermoplastic special engineering plastics. It has good

mechanical properties and chemical resistance, abrasion resistance, and hydrolysis resistance properties

etc.; it has a light proportion and self-lubricating properties.

Product Parameters Of PEEK board / sheet / plate

The Main Properties of PEEK

|

Property |

Item no. |

Unit |

PEEK-1000 |

PEEK-CA30 |

PEEK-GF30 |

|

1 |

Density |

g/cm3 |

1.31 |

1.41 |

1.51 |

|

2 |

Water absorption(23℃ in air) |

% |

0.20 |

0.14 |

0.14 |

|

3 |

Tensile strength |

MPa |

110 |

130 |

90 |

|

4 |

Tensile strain at break |

% |

20 |

5 |

5 |

|

5 |

Compressive stress(at 2% nominal strain) |

MPa |

57 |

97 |

81 |

|

6 |

Charov impact strength(unnotched) |

KJ/m2 |

No break |

35 |

35 |

|

7 |

Charov impact strength(notched) |

KJ/m2 |

3.5 |

4 |

4 |

|

8 |

Tensile modulus of elasticity |

MPa |

4400 |

7700 |

6300 |

|

9 |

Ball indentation hardness |

N/mm2 |

230 |

325 |

270 |

|

10 |

Rockwell hardness |

-- |

M105 |

M102 |

M99 |

PEEK board / sheet / plate Material Characteristics

1. Mechanical properties (variable stress and excellent fatigue resistance)

2. High temperature resistance (long-term use at 260℃)

3. Self-lubricity (low coefficient of friction and wear resistance)

4. Chemical resistance (corrosion resistance)

5. Flame retardant (can reach the highest flame retardant standard)

6. Peeling resistance (can be made into thin coated or electromagnetic wire)

7. Fatigue resistance (resin material has the best fatigue resistance)

8. Hydrolysis resistance (excellent in high temperature and high pressure water)

9. Radiation resistance (up to 1100Mr AD)

Product Advantages of PEEK board / sheet / plate

Heat-resistance

PEEK has a higher glass transition temperature and melting point(334°C). It is one of the reasons that it can

be a reliable application in the requirement ofthe heat.Its heat load variable-tem perature can be 316°C ,

continuous use temperature is 260℃.

Self-lubricating

PEEK has outstanding sliding characteristics in all plastics;it is suitable for stringent requirements for low

coefficient of friction and resistance to friction used. Especially the self-lubricating properties of PEEK will be

better if it is modified by carbon fiber and graphite mixed in the proportion of each of them.

Chemical Resistance

PEEK has excellent chemical resistance. In ordinary chemicals, it can be dissolved or damaged only by

concentrated sulfuric acid; its corrosion resistance is similar to those of steel and nickel.

Hydrolysis Resistance

PEEK and its composites will not be affected chemically by water and high pressure steam. The products

that are made from this material will maintain the outstanding characteristics in continuous use in high

temperature and high pressure water

Besides, PEEK can be used to produce some exact medical equipments for the OPS and dentistry, which

can annihilate bacterium and can be used time after time, the most important application of PEEK, which is

used to produce the artificial bone instead of metal. The artificial bone, which is made of PEEK, has the

good performance of light-weight, non-toxic and good-chemical-resistance and so on, and can integrate

with the organism of human body. So PEEK is also successfully applied in medical industries.

For sheet plate rod tube, the products will be sent for 1 day. And we support OEM and ODM.