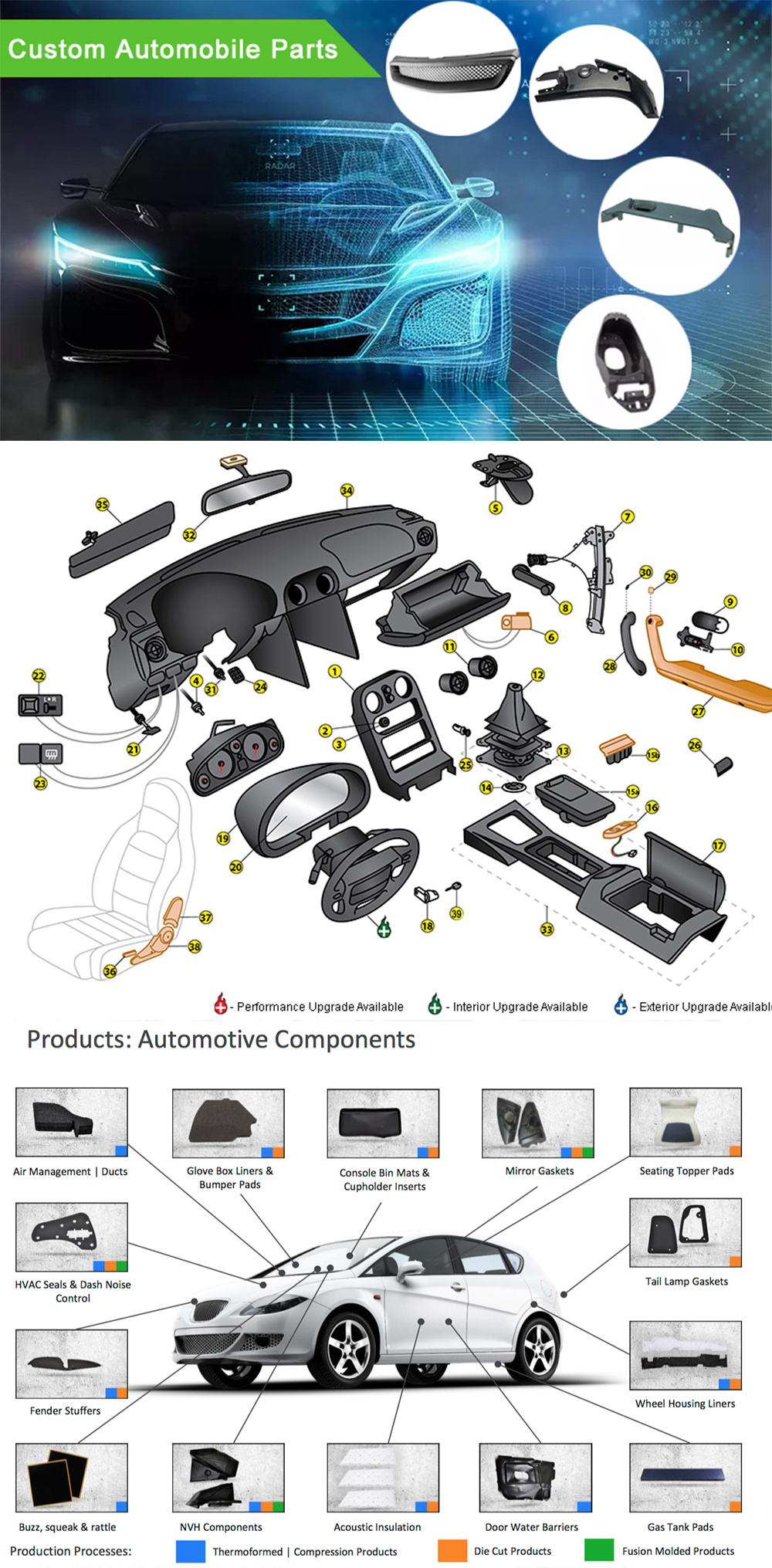

Plastic injection mold auto parts for car accessories We are an injection mold manufacturer specializing in the production of high-precision auto parts for auto accessories. We manufacture molds and injection molding tools for a wide variety of automot

Why injection Moulding Injection Parts ?

For quality , injection is better, the smoothness and flatness can be done on the mold, and the strength is also good. Some transfers during mechanical processing, the sharp edges may be difficult to process beautifully . But mass injection need big quantity to open mould to decrease unit price because of expensive mould .

Plastic injection mold auto parts for car accessories

We are an injection mold manufacturer specializing in the production of high-precision auto parts for auto accessories. We manufacture molds and injection molding tools for a wide variety of automotive components such as interior and exterior trim, door panels, bumpers, mirrors, grilles, headlights and other plastic parts. We have extensive experience in the production of plastic components for the automotive industry. Our engineers are well versed in plastic mold design and injection molding and can provide high quality molds and parts to your specifications.

About the material:

ABS which full name Acrylonitrile butadiene styrene (chemical formula (C8H8)x·(C4H6)y·(C3H3N)z)

is a common thermoplastic polymer. It is a terpolymer made by polymerizing styrene and acrylonitrile

in the presence of polybutadiene.

ABS Features

1. Excellent impact strength, even in low temperature conditions.

2. Good dimensional stability, not easy to deformation and scratch.

3. Excellent forming and machining performance.

4. Low water absorption and good corrosion resistance.

5. Non-toxic and tasteless.

6. Excellent electrical insulation performance.

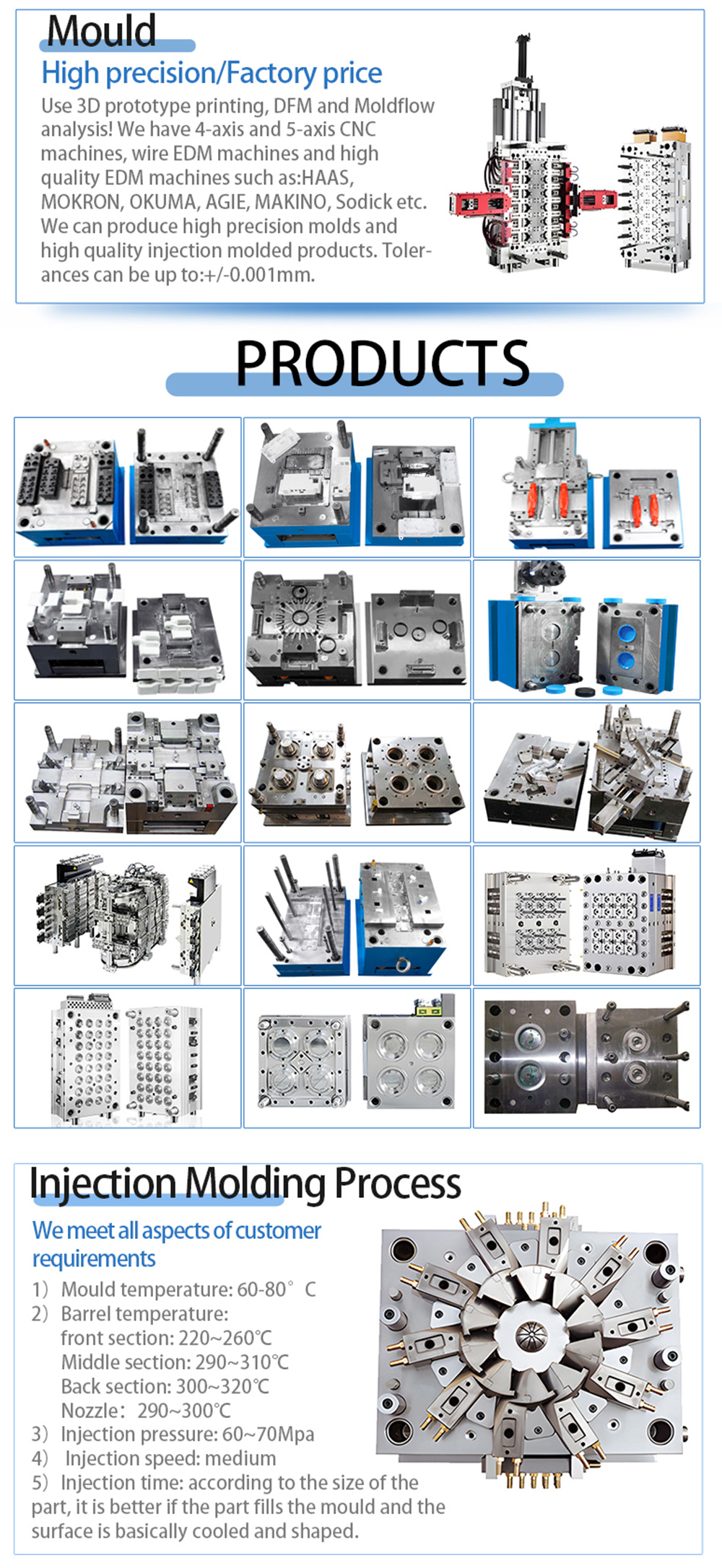

Your project begins when you meet with our expert mold engineers and toolmakers to design precision molds to produce injection molded products with tight micro tolerances. We have the capacity to manufacture over 100,000 parts per day, and we can also successfully produce short-run high-value, high-end specialty medical equipment accessories.

What are the advantages of automotive interior injection molding?

So what are the advantages of plastic injection molding parts for automobiles?

1. The plastic can be processed and formed at one time, the processing time is short, and the accuracy is guaranteed.

2. The elastic deformation characteristics of plastic products for vehicles can absorb a large amount of collision energy, have a greater buffering effect on strong impacts, and protect vehicles and passengers. Plasticized dashboards and steering wheels are used on modern cars to enhance cushioning. The front and rear bumpers and body trim strips are all made of plastic materials to reduce the impact of objects outside the car on the body. Automotive plastics also have the function of absorbing and attenuating vibration and noise, which can improve ride comfort.

3. Automobile plastic injection molded parts have strong corrosion resistance, and local damage will not corrode.

4. By adding different fillers, plasticizers and hardeners to produce plastics with the required properties to meet the requirements of different parts of the car. What's more convenient is that the plastic color can be adjusted to different colors through additives, saving the trouble of painting. Some automotive plastic parts can also be electroplated.

Our capabilities:

1.Drawing software:Customer provide the 2D drawing or 3D data in DXF, DWG, PRT, SAT,

IGES, STP format etc, or just send us the sample.

2.Prototype design and production assembly

3.Material:POM, AS,ABS,PS,PP,PVC,PBT,PE,PMMA,PA etc.

4.Mould Cavity: Single or multi-cavities based on customer' s requirement

5.Mould date:10-25 days

6.Mould life:100,0000shots or as customer's request

7.Surface Finish: chrome plating, silk-printing, texture, color painting etc.

8.Sample confirm: We will send trial sample to customers before shipment,If the sample isn't

satisfied by customers.We will modify mould until customers satisfaction.

Product Paramenter

|

Company Name

|

Guangdong Engineering plastics Industries(Group)Co,Ltd

|

|||

|

Brand

|

Guangdong Engineering plastics

|

|||

|

Main Product

|

Precision mold, Injection mold, Extrusion mold, Injection plastic products, etc

|

|||

|

Injection Machine

(Double Color)

|

88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T

|

|||

|

Application

|

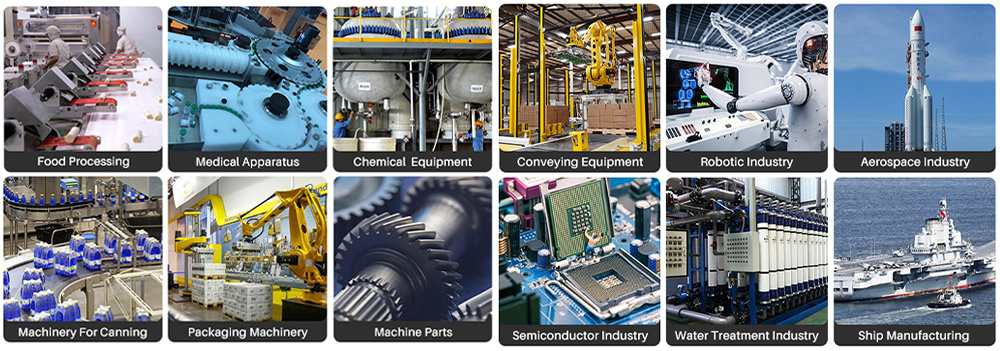

Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc

|

|||

|

Mould Base

|

LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc.

|

|||

|

Mould Material

|

718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD-61, etc

|

|||

|

Moud Precision

|

+/-0.01mm

|

|||

|

Mould Life

|

100k-1000K shots

|

|||

|

Mould Cavity

|

Single cavity, multi-cavity

|

|||

|

Runner System

|

Hot runner and cold runner

|

|||

|

Manufacturing Equipments

|

Guangdong Engineering plastics company has OWM:Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc

|

|||

|

Plastic Raw Material

|

Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc.

|

|||

|

Color

|

white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc

|

|||

|

Surface Treatment Tech

|

Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting…

|

|||

|

Product Drawings

|

2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures

|

|||

|

Lead time

|

15-30 working days for injection moulds,plastic products according to quantity

|

|||

|

Quanlity System

|

ISO 9001, RoHS Srandard, etc

|

|||

|

Our Spirit

|

"Engineering Plastics" can be used instead of "Steel"!

Science and technology will change the future!

Guangdong Engineering Plastics Industries Company!

|

|||

|

Other

|

24 hours instant and comfortable customer service!

|

|||

|

Shipping status notification during delivery!

|

||||

|

Regular notification of new styles & hot selling styles!

|

||||

We have a wide range of customization:Moulding Injection

Industrial Moulding Injection,Electronic Moulding Injection

Automotive Moulding Injection,Medical Moulding Injection

PU Injection Molded Parts

For injection molding, the products will be sent for 15 days. And we support OEM and ODM.

PROFESSIONAL ENGINEER TEAMS AND SALES TEAMS

We have the professional engineer teams and sales teams. The maximum size of engraving machine in our manufacture is 2000mmx4000mmx400mm. Engineers and salesmen have more than 10 years of experience, specializing in medical, electronic and automotive products.

IMPORTED EQUIPMENT

We have the high quality CNC and EDM machine tools from HAAS、MOKRON、OKUMA、AGIE、MAKINO, such as, milling machines and 4 axis CNC milling machines, which have a capacity to process 200mmx4000 screw stably and precisely.

FAST DELIVERY

There are two shifts in the workshop every day. The fastest lead time of the plastic sheets is within one day. Thus, the delivery time is fast.

ONE- STOP SERVICE

We provide product design and 3D printing services. Having 58 engraving machines and CNC milling machine production lines, we can provide manufacture, operation testing and various services.

FACTORY PRICE WITH NICE QUALITY

We have IS09001 international quality management system, and Chinese manufacture cost control experiences! Therefore, when you compare us with others, we can help you save about 20% ~ 30% of manufacturing costs

EXCELLENT AFTER-SALES SERVICE

We provide excellent after-sales services to our clients for 3 years after their receipt of the products . Most of our customers have been working with us for more than 15 years ,with the co ntinuous trust,satisfaction and cooperation with us till now.

We also have multiple certifications ISO SGS FDA etc.

wide range of applications

Household utility ware, Auto components, Computer electronics, Electronics components,

Marketing samples, Medical & dental products, Model shops, toys, hobby,

New product design & development, Furniture Design, Civil Engineering, Construction.

For injection molding, the products will be sent for 15 days. And we support OEM and ODM.