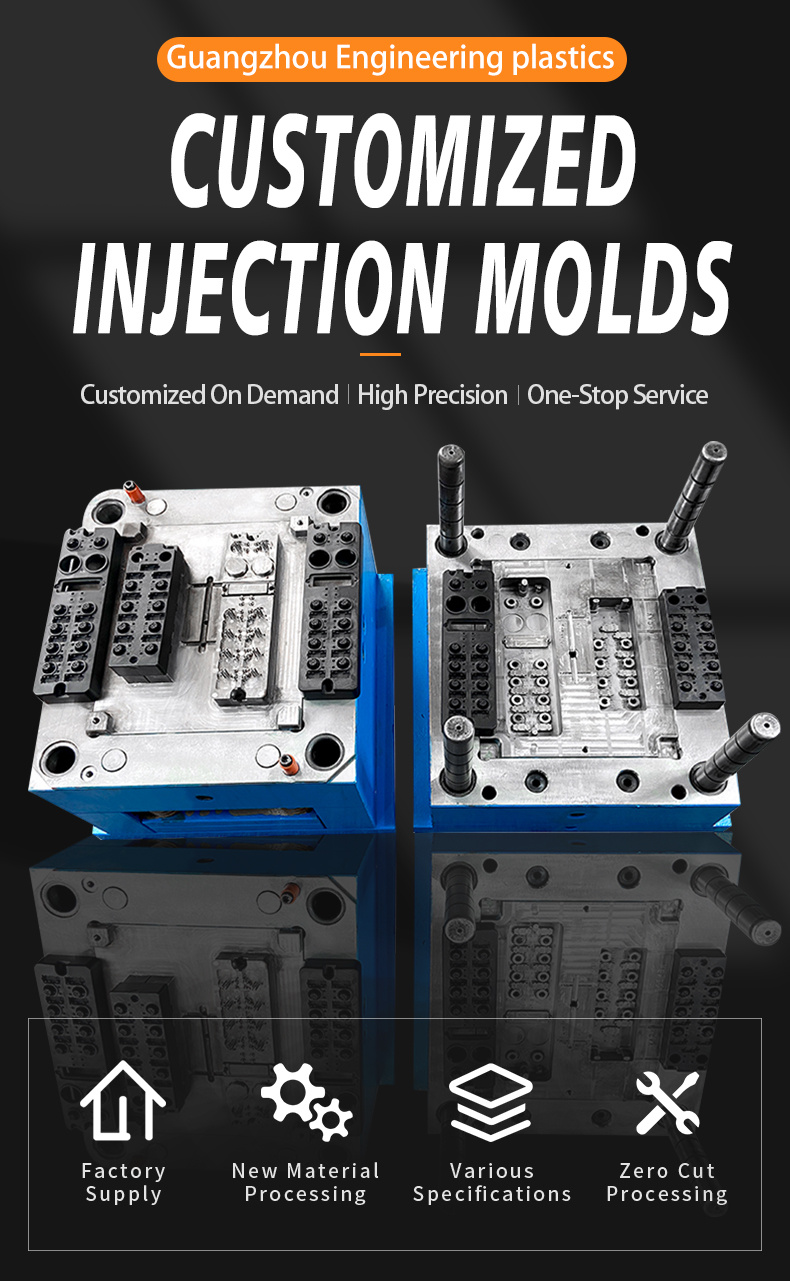

Plastic moulding company plastic mould designs car parts mold automobile injection mold custom plastic injection molding molded Leading Global Injection Molding Supplier Leading Global Injection Molding SupplierAssist global clients in

Assist global clients in engineering material,professional custom injection molding service,CNC machining service.We can provide you with one-stop solutions.

Those plastics materials like UHMW-PE , MY Nylon , PA6 , POM , HDPE , ABS , PU , PC , PVC, PP , PET , PBT , Acrylic , PEEK , PPS , PTFE , PVDF , PAI , PEI , PSU , PI , PBI etc., they have different characteristic ! For example flowing temperature , crystallization speed , heat dispense , viscosity , pressure, speed , deformation and stripping .

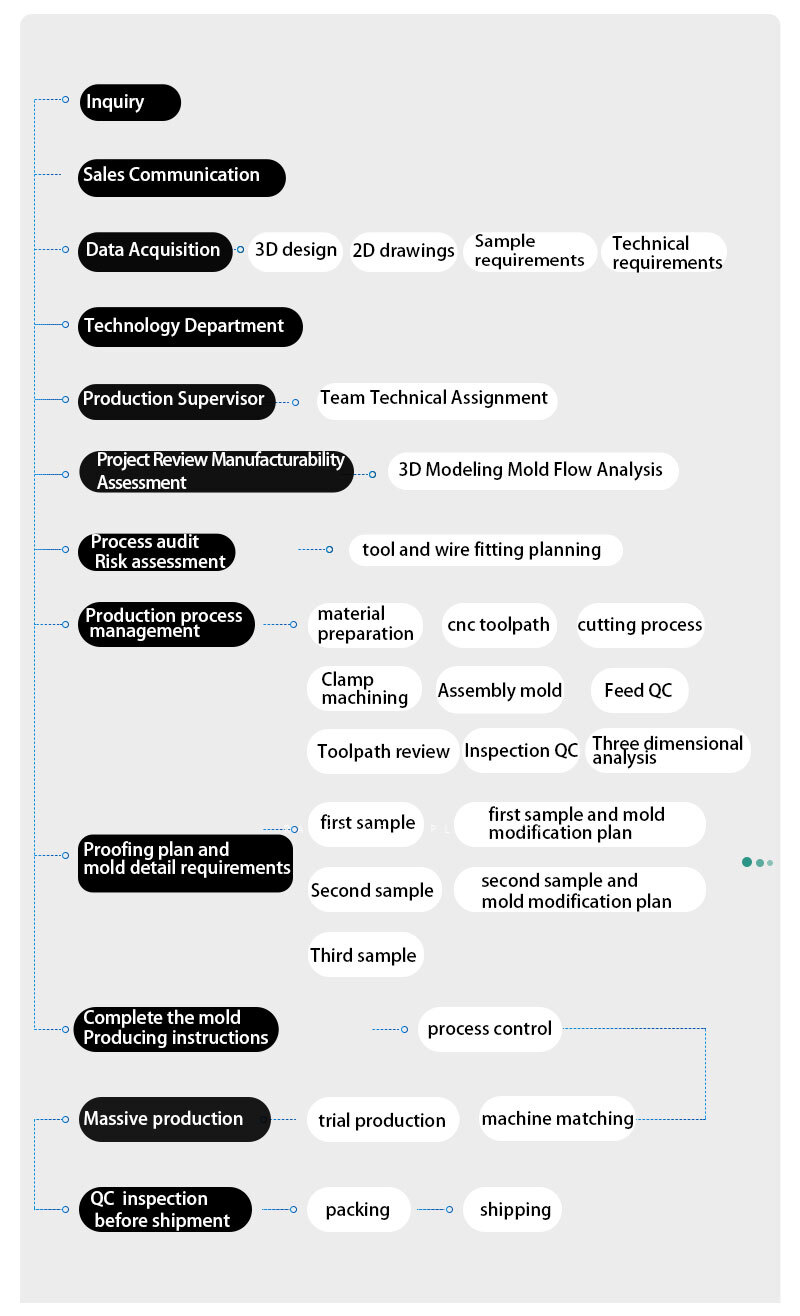

Thanks for clients all along support , we gain lots of successful and failure cases , those experiences we store in database , which guide our new staff avoid same mistake. Today our comprehensive service from industrial design, mold design and manufacturing, volume production and production is based on an end-to-end quality assurance system that delivers an efficient, cost-saving, turnkey solution in plastic injection molding manufacturing.

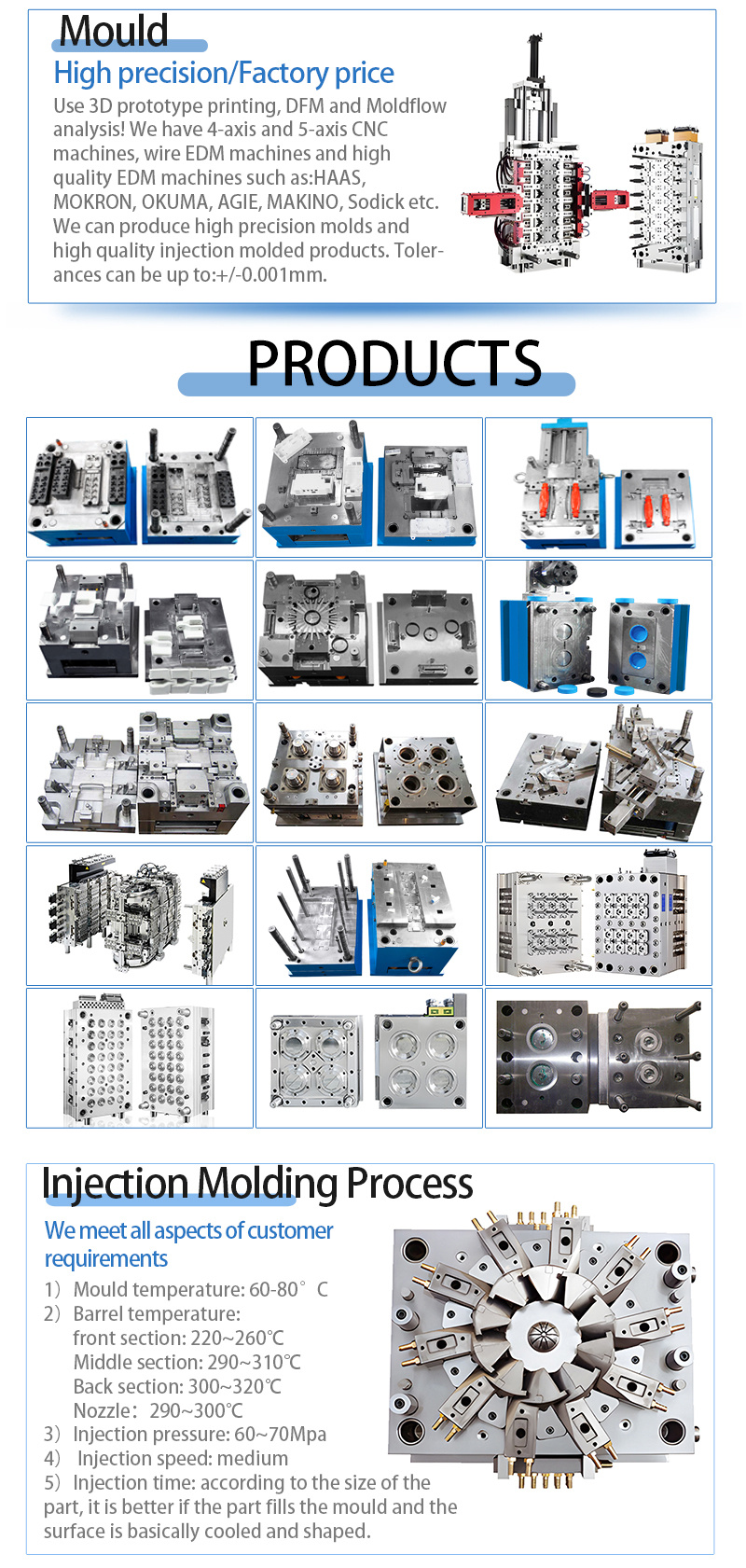

Our mold team uses the lasted new version software design programs: UG, ProE, SolidWorks, Catia, Rhino etc., you can send any type of drawings xmt,step,vad or .iges. We also give you service is reverse engineering, we can follow your sample to create a completely new 3d drawings and the molds.

Our clients include medical industry, automobile, electronics industry, consume plastic products, etc., Our skilled technician and mould maker specialists work with each individual client and use the best material available for each application, Guides your project through each phase of development to save you time and money. We will explain whole process efficiently in five main stages: the production of the technical preparation stage, the preparation stage of raw materials, parts and components processing stage, assembly and commissioning phase trial identification stage. It is clear and confident to achieve success .

Plastic moulding company plastic mould designs car parts mold automobile injection mold custom plastic injection molding molded

We can provide you with one-stop solutions. Request an injection molding quote today.

Product Display

|

Company Name

|

Guangdong Engineering plastics Industries(Group)Co,Ltd

|

|||

|

Brand

|

Guangdong Engineering plastics

|

|||

|

Main Product

|

Precision mold, Injection mold, Extrusion mold, Injection plastic products, etc

|

|||

|

Injection Machine

(Double Color)

|

88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T

|

|||

|

Application

|

Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc

|

|||

|

Mould Base

|

LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc.

|

|||

|

Mould Material

|

718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD-61, etc

|

|||

|

Moud Precision

|

+/-0.01mm

|

|||

|

Mould Life

|

100k-1000K shots

|

|||

|

Mould Cavity

|

Single cavity, multi-cavity

|

|||

|

Runner System

|

Hot runner and cold runner

|

|||

|

Manufacturing Equipments

|

Guangdong Engineering plastics company has OWM:Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc

|

|||

|

Plastic Raw Material

|

Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc.

|

|||

|

Color

|

white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc

|

|||

|

Surface Treatment Tech

|

Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting…

|

|||

|

Product Drawings

|

2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures

|

|||

|

Lead time

|

15-30 working days for injection moulds,plastic products according to quantity

|

|||

|

Quanlity System

|

ISO 9001, RoHS Srandard, etc

|

|||

|

Our Spirit

|

"Engineering Plastics" can be used instead of "Steel"!

Science and technology will change the future!

Guangdong Engineering Plastics Industries Company!

|

|||

|

Other

|

24 hours instant and comfortable customer service!

|

|||

|

Shipping status notification during delivery!

|

||||

|

Regular notification of new styles & hot selling styles!

|

||||

Injection Process

Our Factory

(Our factory has 100 sets of precision processing equipment, welcome to visit our factory!)

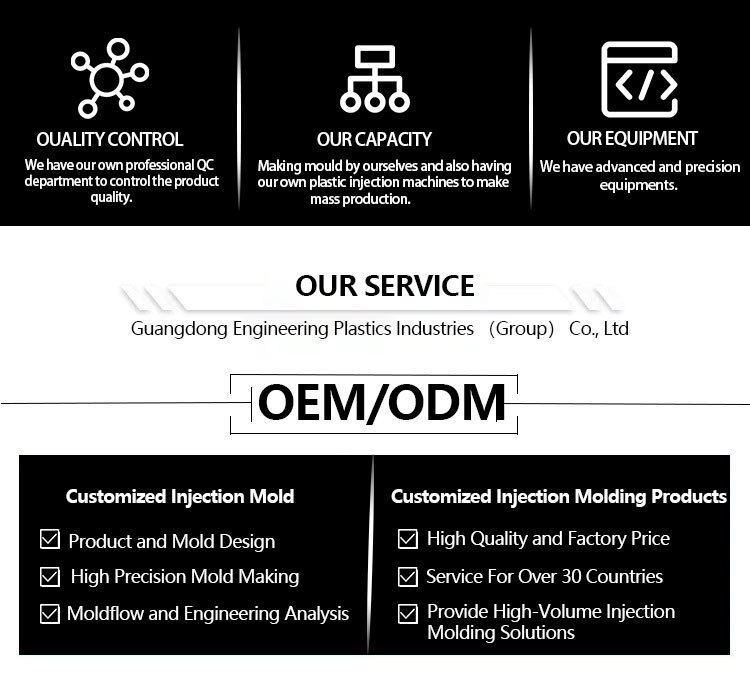

Reliable mold expert 15+ years' experience, Cooperated with many world famous brands for many years, Specialize in large and complex injection mold making, One-stop service from design to production.

Certificate

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Professional Team

Guangdong Engineering Plastics Industries Co., Ltd! We have the professional engineer teams and sales teams, and we have technology and experiences in engineering plastic industry for morethan 15 years! Our company is located in Huangpu District, Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design,research and development ability, support personalized customization. We have full set of high efficiency producing equipment and advanced numerical control machines, such as: molding injection machines, CNC molding manufacture machines, fine carving machines, Horizontal lathes, milling machines. We can customize all kinds of Engineering plastics products according to our customers’drawings or samples.

Our company is developing in the mode of quality for survival, brand for development and customer's demand, welcome new and old customers to visit our factory for guidance.

Customers Witness

Our Exhibition & CCTV Interview

Application

Cooperation